The heart within your Mercedes Sprinter's engine cooling program may be the water pump. This crucial ingredient tirelessly circulates coolant, avoiding overheating and guaranteeing optimum general performance, Primarily underneath the demanding disorders commercial automobiles frequently face. When it's time to get a substitute (specifically for element range 6022000220), the selection you make can significantly impression trustworthiness, longevity, and in some cases gas performance. Two well known alternatives emerge: FREY, specializing in OEM-stage aluminum pumps, and RM European, a respected identify known for classic Forged iron or composite types, generally dispersed by associates like RM European. building the appropriate determination needs searching outside of the area and knowledge the fundamental variances in components, technological innovation, and validation procedures used by these water pump suppliers. this informative article dives deep into a comparative analysis, examining housing resources, sealing systems, area therapies, and longevity promises that can assist you decide on the h2o pump that most closely fits your Sprinter's wants as well as your operational priorities.

Table of contents:

enterprise Profiles: environment the Stage

Housing Material Deep Dive: Aluminum vs. Forged Iron/Composite

Sealing technologies: The Leak Prevention Battleground

area remedies and Corrosion Protection

extensive-Term toughness and Validation

summary and advice

organization Profiles: environment the Stage

being familiar with the philosophy and market position of each brand name delivers very important context.

FREY

https://www.freyparts.com/

FREY: FREY positions by itself to be a Leading water pump provider focused squarely around the superior-finish commercial vehicle section, particularly Mercedes-Benz platforms such as the Sprinter. Their core value proposition revolves all over manufacturing sections that meet or exceed initial tools company (OEM) requirements. This determination is underscored by their claim of arduous bench testing For each and every unit, making certain compatibility, effectiveness, and longevity that aligns with Mercedes-Benz standards. Their use of contemporary products like aluminum alloys demonstrates a focus on modern day engineering demands for efficiency and thermal management.

RM European

https://www.rmeuropean.com/

RM European (by using RM European): RM European is really a well-proven German maker that has a long historical past from the automotive aftermarket. They are really recognized for creating responsible drinking water pumps, normally employing regular supplies like Solid iron or sturdy composite plastics, which have served motor vehicles perfectly for decades. Their energy lies in verified layouts and huge coverage across various motor vehicle types, together with many basic and workhorse Mercedes purposes. Distributed via dependable channels like RM European, RM European pumps stand for a trustworthy, normally Price tag-successful, alternative selection backed by set up manufacturing methods.

Housing product Deep Dive: Aluminum vs. Forged Iron/Composite

The material employed for the drinking water pump housing is arguably the most vital differentiator, influencing bodyweight, warmth transfer, corrosion resistance, and manufacturing procedures.

pounds and Thermal Conductivity:

oFREY (Aluminum Alloy): Aluminum's primary edge is its appreciably decreased density when compared to Forged iron. This translates on to excess weight price savings – a small but cumulative benefit for In general car or truck pounds, possibly contributing to marginal gas economic climate enhancements and a little much better handling dynamics. far more critically, aluminum features exceptional thermal conductivity. This means the FREY pump housing alone can dissipate heat a lot more efficiently and immediately transfer heat in the motor block in to the coolant, aiding the cooling program's overall performance, Specially throughout higher-load Procedure or in incredibly hot climates.

oRM European (Forged Iron/Composite): Forged iron is considerably heavier, introducing additional mass on the motor assembly. whilst strong, its thermal conductivity is lessen than aluminum's, that means the housing itself contributes fewer to warmth dissipation. Composite housings offer a Center floor, lighter than iron but likely much less conductive than aluminum, even though featuring great corrosion resistance and style and design versatility. Forged iron's mass, however, does lend it inherent vibration damping Attributes.

Corrosion and exhaustion Resistance:

oFREY (Aluminum Alloy): Aluminum The natural way forms a passive oxide layer (aluminum oxide) on publicity to air, supplying inherent corrosion resistance. even so, aluminum alloys can be susceptible to pitting corrosion or galvanic corrosion (if improperly set up with dissimilar metals devoid of acceptable coolant inhibitors) around extended periods, especially if coolant high quality degrades. To combat this, higher-high-quality aluminum pumps like FREY's typically incorporate protecting area treatments (talked over later). Aluminum commonly reveals very good fatigue resistance beneath normal working stresses.

oRM European (Solid Iron/Composite): Cast iron's primary vulnerability is rust (iron oxide) Should the coolant's anti-corrosion additives are depleted or the incorrect coolant sort is used. correct cooling program upkeep is very important. nonetheless, cast iron is very immune to affect and abrasion, which makes it pretty durable physically. Its exhaustion daily life is usually excellent below typical circumstances. Composite housings are inherently proof against rust and many sorts of chemical corrosion present in cooling methods, featuring a resilient alternative, While their very long-phrase resistance to warmth biking and opportunity brittleness compared to metal needs thing to consider.

producing procedure and style and design:

oFREY (Aluminum Alloy): Aluminum alloys are well-suited for contemporary die-casting processes. This enables with the development of intricate inside move passages and skinny-walled constructions with significant precision. This precision can improve coolant movement dynamics inside the pump, perhaps bettering hydraulic effectiveness and contributing to better In general cooling performance.

oRM European (Cast Iron/Composite): Solid iron housings are usually made making use of sand casting, a experienced and price-helpful strategy ideal for large-quantity output. when capable of manufacturing elaborate styles, it may offer you marginally less precision in intricate internal specifics when compared to die-casting aluminum. Composite housings will often be injection molded, allowing important design and style liberty and most likely reduced producing expenses than casting steel.

Sealing know-how: The Leak Prevention Battleground

The seal may be the h2o pump's Achilles' heel. avoiding coolant leaks is paramount, and sealing know-how has developed noticeably.

The Evolution of Seals: Early h2o pumps relied on basic packing or fundamental lip seals. later on, paper or cork gaskets had been typical for sealing the pump housing to your engine block. Modern layouts predominantly use subtle mechanical confront seals combined with elastomeric O-rings or bellows.

FREY (modern-day Multi-Layer/Innovative Elastomer Seals): FREY emphasizes the use of fashionable sealing methods, most likely incorporating mechanical encounter seals (typically ceramic and carbon mating rings) held together by a spring, coupled with substantial-top quality, multi-layered or especially formulated elastomer elements (like HNBR or FKM rubbers). These Superior seals are meant to:

oWithstand higher temperatures and pressures popular in contemporary engines.

oMaintain sealing integrity all through speedy temperature fluctuations (chilly begins to incredibly hot operating).

oResist degradation from complex coolant additives and probable contaminants.

oOffer substantially for a longer period service everyday living just before weeping or leaking occurs when compared with more mature styles. The reference to Guanseal probably points to a specific significant-efficiency seal maker or structure philosophy focused on longevity.

RM European (Traditional Paper Gaskets/solitary-Layer Seals): when RM European probable works by using reliable mechanical seals internally, their housing-to-block sealing may possibly depend upon additional classic solutions dependant upon the specific application and structure period. more mature layouts could use taken care of paper gaskets or typical one-layer rubber O-rings or gaskets. when efficient when new, these products may be much more susceptible to:

oCompression established with time (getting rid of their sealing power).

oBecoming brittle or cracking due to warmth cycles and age.

oDegradation from intense coolant chemistries or contamination.

oHigher danger of leakage, notably for the duration of chilly starts or Extraordinary higher-rpm/large-tension situations, in comparison to Innovative multi-part sealing programs.

surface area therapies and Corrosion security

Beyond The bottom substance, surface remedies play a significant position in longevity, especially for aluminum housings.

FREY (Anodizing): FREY highlights using anodizing for its aluminum housings. Anodizing electrochemically converts the aluminum area into a layer of long lasting, challenging, corrosion-resistant aluminum oxide. This layer is integral on the steel (not just a coating) and delivers:

oExcellent defense against oxidation and chemical assault from coolant.

oIncreased area hardness, supplying some dress in resistance.

oA cleanse, environmentally friendly procedure when compared to some paints.

RM European (Paint/Coatings or organic complete): Solid iron pumps in many cases are painted (e.g., with epoxy paint) to avoid exterior rust and supply a completed visual appeal. though successful at first, paint levels can chip or peel with time as a result of warmth, vibration, or impacts, likely exposing the fundamental iron to corrosion In the event the coolant inhibitors are unsuccessful. Composite pumps usually demand no supplemental corrosion protection. Some higher-end pumps across the industry (referenced by Wikipedia regarding normal know-how) may well use specialised coatings like phosphate conversion coatings or maybe abradable powder coatings on internal surfaces to optimize clearances and increase efficiency, although this is usually reserved for high quality apps.

very long-Term toughness and Validation

promises of longevity are easy to make; validation is key.

FREY (demanding Bench Testing): FREY's declare of one hundred% bench testing Every device provides a significant top quality assurance evaluate. This screening most likely simulates motor operating problems (flow, strain, temperature cycles) to validate seal integrity, bearing efficiency, and impeller operate. Their assertion of obtaining one.5 occasions the lifespan of rivals implies self-assurance derived from this testing and their preferred elements/style. This aligns with their give attention to Conference OEM longevity standards.

RM European (Proven Track Record & normal Lifespan): RM European relies on its long-standing reputation and also the proven longevity of common components. whilst Possibly not independently bench-testing each and every aftermarket device to precisely the same extent claimed by FREY, their patterns are depending on a long time of real-world application. typical market facts (like that referenced from STREAMPUMPS or standard guides) suggests that a drinking water pump in a very perfectly-managed cooling process (proper coolant, frequent flushes) can last a hundred,000 miles or 10-15 several years, but this is highly variable. vital aspects influencing real lifespan incorporate the caliber of the seal and bearing components, the housing content's resistance to corrosion/erosion, and, critically, the diligence of procedure maintenance (as highlighted by final Guide To h2o Pumps).

Conclusion and advice

Choosing involving the FREY aluminum h2o pump as well as the RM European cast iron/composite h2o pump for the Mercedes Sprinter 6022000220 entails balancing priorities:

Prioritize light-weight design and style, Thermal Efficiency, and OEM-amount Validation: If minimizing body weight, maximizing cooling program responsiveness (In particular beneath load), and making sure adherence to stringent OEM-degree screening and specs are your Key ambitions, the FREY aluminum pump with its anodized end and Highly developed sealing technological know-how may be the superior selection. It signifies a modern engineering strategy focused on overall performance and verified sturdiness.

Prioritize verified common structure and Original Charge: when you value a lengthy-founded style utilizing robust, conventional resources and they are most likely far more sensitive into the Preliminary obtain selling price, the RM European pump provides a dependable and price-effective Resolution. Its Solid iron or composite design features a verified track record, provided the cooling system is correctly maintained.

think about Longevity and small routine maintenance: For apps where maximizing some time in between replacements and minimizing the chance of leaks over the prolonged haul is critical (important for professional fleet operators), FREY’s mix of corrosion-resistant dealt with aluminum, Highly developed multi-layer sealing, and claimed rigorous validation screening provides a compelling argument for most likely lower complete price of ownership, In spite of a quite possibly bigger Preliminary outlay.

Ultimately, the read more choice rests on your own specific demands, driving problems, servicing techniques, and spending budget. on the other hand, for demanding commercial use in which reliability and extended-time period efficiency are paramount, aligning with factors validated to stringent benchmarks is usually the wisest financial commitment. Therefore, very carefully take into account the benefits of advanced materials and verified tests protocols made available from suppliers like Frey.

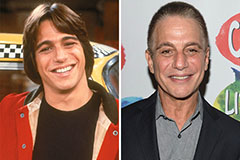

Tony Danza Then & Now!

Tony Danza Then & Now! Hailie Jade Scott Mathers Then & Now!

Hailie Jade Scott Mathers Then & Now! Loni Anderson Then & Now!

Loni Anderson Then & Now! Christy Canyon Then & Now!

Christy Canyon Then & Now! Lacey Chabert Then & Now!

Lacey Chabert Then & Now!